|

|

|

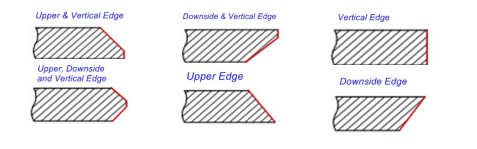

Our XBJ series edge milling machine is designed with large power milling head and enlarged body base. This edge milling equipment is an efficient and advanced equipment for processing plate/sheet before welding. Compared with edge planer, edge milling machine can save power & cost, and provide enough roughness for surface. Therefore, it is a necessary equipment for many industries such like pressure containers, shipping yards, electronics, chemicals, and metal structures. Following edges can be formed with our edge milling machine:

1. The position of the cutter plate can be adjusted freely to achieve straight chamfering and any direction edge. Milling speed of our edge milling equipment is variable and adjustable through inverter. Designed with 7.5kW milling heads, this edge milling machine enjoys larger power and higher efficiency compared with 5.5kW milling head.

2. Our edge milling equipment can mill upper/bottom and straight edges, and the angle can be freely adjusted within 0-45oto achieve chamfering edges with different angles.

3. By using different blades, our edge milling machine can mill different materials such as carbon steel, alloyed steel, stainless steel, etc. We provide a Φ125mm cutter with machine when delivery.

4. The edge milling equipment is designed with welded structure, and stress release is treated after welding. So deformation is reduced and stable working can be assured.

5. The guides of this edge milling machine are fixed to the main body by bolts, and the guides are made of 45# mild steel and finely processed, with surface quenched and finely milled for enhanced precision and wear resistance.

6. Milling feed device of our edge milling equipment is driven by motor and gearbox, with speed variable from 0.15 to 1m/min and return speed up to 4m/min.

7. Hydraulic jacks are designed instead of mechanical jacks to provide powerful and stable pressure and reduce vibration & noise when milling.

8. Press beam and machine body are connected directly for good rigidity.

9. The traveling guides are parallel. The upper guide is protected by protection cover to avoid damage by dropped scraps or dust. The bottom guide is protected by dust remover on the traveling device.

10. Customers can load two or more small sheets on the machine. Two or more plates can be loaded and clamped separately.

| Model

| XBJ-6

| XBJ-9

| XBJ-12

| XBJ-18

|

|

Beveling stroke (m)

| 6

| 9

| 12

| 18

|

|

Beveling range

| 0-45°

| 0-45°

| 0-45°

| 0-45°

|

|

Beveling sheet thickness (mm)

| 6-50

| 6-50

| 6-50

| 6-50

|

|

Max beveling depth (mm)

| 12-15

| 12-15

| 12-15

| 12-15

|

|

Transverse beveling speed (m/min)

| 0.3/0.5

| 0.3/0.5

| 0.3/0.5

| 0.3/0.5

|

|

Return speed (m/min)

| 5

| 5

| 5

| 5

|

|

Spindle speed (rpm)

| 125-900

| 125-900

| 125-900

| 125-900

|

|

No. of milling head

| 1 (+1)

| 1 (+1)

| 1 (+1)

| 1 (+1)

|

|

Milling head power (kW)

| 7.5

| 7.5

| 7.5

| 7.5

|

|

Platform height (mm)

| 900

| 900

| 900

| 900

|