Wind Tower Production Line

Description

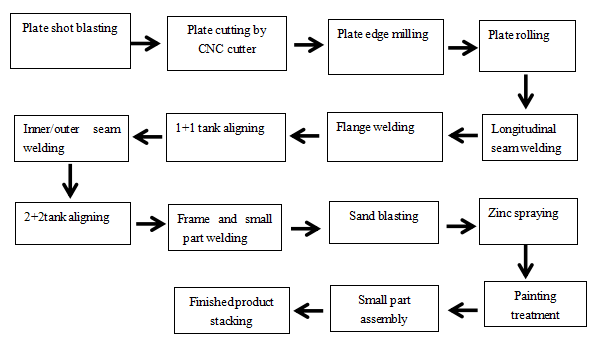

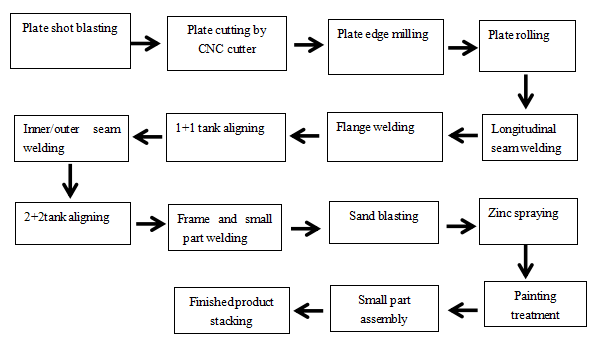

Our wind tower production line consists of the following equipment: plate shot blasting machine, CNC cutting machine, plate edge milling machine, plate rolling machine, flange aligning platform, 1 +1 aligning rotator, straight seam welding machine with welding rotators, inner/outer seam welding machine with 2+2 aligning rotator and welding rotator (fit-up growing line), sand blasting welding rotators and painting welding rotators.

This wind tower production line is mainly used for assembly welding of round (or small-angle tapered) workpieces. It connects the towers by adjusting the height, position and inclination of tower sections through the aligning rotator. The connected towers will then be conveyed to connect with other towers, until all the sections are connected and the inner/outer seams are welded.

The wind tower production line designed and manufactured by our company has the characteristics of compact structure, simple layout and reasonable space arrangement. The motor, reducer, bearing and electric accessories are from global-leading brands to ensure the reliability and service life. All the equipment of the production line has been certified by CE, and meet the requirements of EU importing economies.

Work Process

Plate Shot Blasting Machine

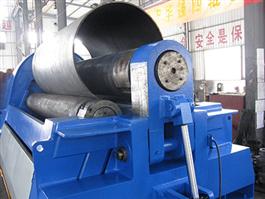

Plate Shot Blasting Machine Plate Rolling Machine

Plate Rolling Machine Welding Manipulator

Welding Manipulator Painting Welding Rotator

Painting Welding Rotator