|

|

|

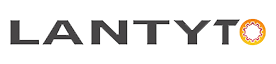

Welding Manipulator

Welding Manipulator

Welding Rotator

Welding Rotator

Welding Positioner

Welding Positioner

Plate Shot Blasting Machine

Plate Shot Blasting Machine

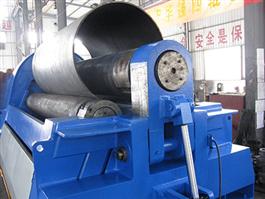

Plate Rolling Machine

Plate Rolling Machine

Welding Manipulator

Welding Manipulator