-

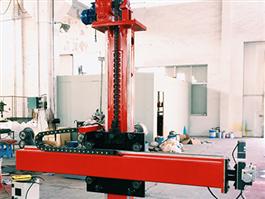

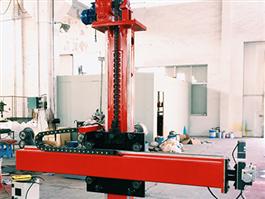

Welding Manipulator

Welding Manipulator

-

Welding Rotator

Welding Rotator

-

Welding Positioner

Welding Positioner

-

Customized Welding Solution

Customized Welding Solution

-

Plate Shot Blasting Machine

Plate Shot Blasting Machine

-

CNC Cutting Machine

CNC Cutting Machine

-

Edge Milling Machine

Edge Milling Machine

-

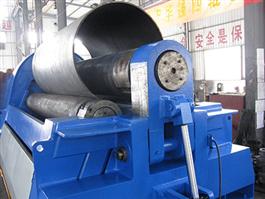

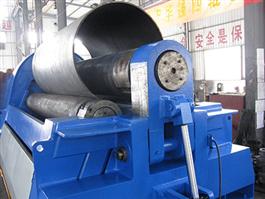

Plate Rolling Machine

Plate Rolling Machine

-

Welding Manipulator

Welding Manipulator

-

Fit-up Rotator

Fit-up Rotator

-

Fit-up Growing Line

Fit-up Growing Line

-

Sand Blasting Welding Rotator

Sand Blasting Welding Rotator

-

800Kg Rotary Positioner

800Kg Rotary Positioner Our Welding positioner is designed rotate round or tubular work pieces such as flanges and pipes through 3...

A welding rotator positions the cylindrical jobs whether on light or heavy fabrication shops, the use of a welding rotator provides increased production with reduced labour because it requires less usage of lifting or crane facilities, which also reduces idle time.

Adaptable for both automatic and manual welding works, using this type of welding machine helps attain exceptional quality circumferential joints on shells. It is mainly used for welding of pipes, API pipes, heat exchangers, mounted vessels, boilers, LPG bullets, barrels, pressure vessels and tanks.

Welding Rotators or Turning Rolls as they are sometimes called are useful accessories in welding fabrication workshops, designed to keep in place and to rotate heavy cylindrical parts around a horizontal axis, at a constant and steady turning speed in front of a welding head.

Alternatively they may be rotated in steps until a needed position is reached, and then locked in place for making a longitudinal weld with a welding head mounted on a traveling carriage.

Turning rolls permit to perform circumferential welds in a vertical plane. They are also used for surfacing (cladding), or depositing by welding a filler metal of useful properties on the external or on the internal surface of a hollow cylinder.

Turning Rolls are usually arranged in sets including a pair of identical rolls, one of which is rotated by an electric motor through a reduction gear box, known at the powered or drive unit while the other is idle, so arranged that the distance between the rolls can be adjusted to accommodate cylinders of different diameters, and mounted on a fabricated frame of simple shape.

Usually a pair of such frames must be arranged on the shop floor at some distance from one another, to accept the cylindrical body in need of welding.

Weight capacity and diameters that can be supported are the major parameters that define rotators. Other characteristics involve wheel and surface materials, power and surface speed available.

The free turning of the part on the rolls should be ascertained before the start of the welding operation, to verify that no protrusions interfere with the motion. Also the longitudinal weight distribution should be checked to prevent overloading.

Special attention should be paid to avoid instabilities that may cause the work piece to overturn. Minute inaccuracies of positioning may involve translation of the work piece along its axis.

None parallel or out of square turning rolls may cause drag forces that tend to move the work piece unpredictably.

Welding Rollers are supplied with steel, rubber or polyurethane

Although Welding Rotators are simple positioners, they should be maintained in proper service condition at all times. One should approach every job and every part with care, seriously and thoroughly, possibly following a standard check list, and learning from previous experience.

Welding turning rolls are used in large scale welding factories for elevated efficiency and safety in the work stations. The welding turning roll is also known as self-aligned rotators or self-aligning rotators. Other names applicable to this equipment is conventional turning rolls or pipers, they are all the same type of welding devices though they work at different capacities.

The following is a brief but hopefully informative insight into the world of turning rolls, which will seek to at least give you a basic understanding of the same and their application.

Welding Manipulator

Welding Manipulator

Welding Rotator

Welding Rotator

Welding Positioner

Welding Positioner

Plate Shot Blasting Machine

Plate Shot Blasting Machine

Plate Rolling Machine

Plate Rolling Machine

Welding Manipulator

Welding Manipulator