-

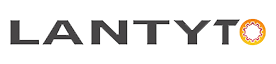

Welding Manipulator

Welding Manipulator

-

Welding Rotator

Welding Rotator

-

Welding Positioner

Welding Positioner

-

Customized Welding Solution

Customized Welding Solution

-

Plate Shot Blasting Machine

Plate Shot Blasting Machine

-

CNC Cutting Machine

CNC Cutting Machine

-

Edge Milling Machine

Edge Milling Machine

-

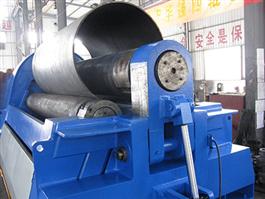

Plate Rolling Machine

Plate Rolling Machine

-

Welding Manipulator

Welding Manipulator

-

Fit-up Rotator

Fit-up Rotator

-

Fit-up Growing Line

Fit-up Growing Line

-

Sand Blasting Welding Rotator

Sand Blasting Welding Rotator

The long table welding rotators are built in capacities from 5 ton to 250 ton.According to capacity load,the rotator wheels are of PU or FULL metals,which can ensure the support capacity and main...

-

Light Duty Turning Rolls

Light Duty Turning Rolls The light duty turning rolls built from min 1ton to max 5ton. Wheels are in 45# steel covered by PU. Foo...

Welding is one of the important processing method in the manufacturing, due to the rapid development of

modern science and technology and a number of factors, the welding process is experiencing the transition

from manual welding and automatic welding. Welding process automation and robotic nanomanipulation and

intelligent has become the inexorable trend of welding industry development.

Welding automation refers to in the absence of people directly involved in the case, with automatic control,

automatic adjustment, testing, processing machinery, equipment, instrumentation, in a specified program

or command automatically, by heat, pressure, or both, and make the two artifacts produced between

atoms combine technical measures. Its aim is to increase production, improve quality, reduce cost and

labor intensity, to ensure the safety of production, etc. Automation has become a measure of the modern

state science and technology and one of the important symbol of the levels of economic development.

Modern automation technology mainly rely on computer control technology to realize, is the direction of the

welding structure production technology development, program control and digital control was realized.

Computer control system in the role of various kinds of automatic welding and cutting equipment is not

only control the welding parameters, and must be able to automatically coordinated sets of welding

equipment of the movement of each component, realize unmanned operation, namely implement welding

production of numerical control, automation and intellectualization. And the use of robots make computer

technology in welding industry has a wider use. Using robot welding has became the prime symbol for the

modernization of welding automation technology. Due to welding robot possesses the advantages of

strong commonality, reliable operation, more and more attention by people. In automatic welding

production line, to promote and expand nc welding and welding robot manipulator, can improve the

productivity and production levels, improve the labor safety and hygiene conditions, stability, and ensure

the quality of welding, welding automation products in batches. Welding process automation, intelligent is

to improve the stability of welding quality, solve the important direction of poor Labour conditions.

Improve the level of automation is the focus direction of the advanced industrial countries in the world, and

to realize automatic welding is also is our ideal and goal. Foreign industrial advanced country in the new

welding technology on the concrete application of many successful performance; In China the study of the

automatic welding technology, equipment manufacturing enterprises also have made great progress,

accumulated a certain technology, talent, manufacturing experience, part of the automatic welding

technology and equipment level has reached the international advanced level, there are a lot of use cases,

individual products are also exported to overseas; The constant improvement of modern rapid development

of its new technology; The state of equipment manufacturing industry development encourages policy;

These conditions have, will speed up to promote the Chinese welding industry technology and equipment

upgrades. Welding technology in the future, on the one hand, to the development of new welding method,

welding equipment andwelding materials, to further improve the welding quality and safe reliability, on the

other hand to improve welding mechanization and automation level, such as welding machine; Developed

from the preparation process of quality control, welding to the whole process automation of special welding

machine; In automatic welding production line, to promote and expand nc welding and welding robot

manipulator, can improve the level of welding production, improve the welding condition of health and safety.

China's reform and opening up 30 years of economic construction has made great progress, and related

fields in welding industry progress very fast these years, China's economic conditions, industrial base,

industrial workers skills and qualities, and the concept of enterprise management level has reached a

higher level, so the Chinese welding industry has the premise condition of rapid development to the

automatic and intelligent.

In recent years, with the vigorous development of the manufacturing industry, improve the productivity of

welding production, ensure product quality, realize the automation of welding production and intelligent by

welding production enterprises more and more attention. Involve more than one interdisciplinary

automation technology, therefore, the development of welding automation must lead the whole

manufacturing production efficiency, the integrated application of analysis and research, to promote the

development of modern science and technology system, has a certain theoretical significance and practical

significance. Can predict, China welding industry automation, intelligent time has come!