Home >

Tradeoffer > Pole Rotating Machine Motorized Elevation Self Centering PLC Connection with Robot

-

Welding Manipulator

Welding Manipulator

-

Welding Rotator

Welding Rotator

-

Welding Positioner

Welding Positioner

-

Customized Welding Solution

Customized Welding Solution

-

Plate Shot Blasting Machine

Plate Shot Blasting Machine

-

CNC Cutting Machine

CNC Cutting Machine

-

Edge Milling Machine

Edge Milling Machine

-

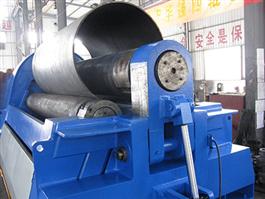

Plate Rolling Machine

Plate Rolling Machine

-

Welding Manipulator

Welding Manipulator

-

Fit-up Rotator

Fit-up Rotator

-

Fit-up Growing Line

Fit-up Growing Line

-

Sand Blasting Welding Rotator

Sand Blasting Welding Rotator

The Tank Rotators are built in capacities from 3 tons to 200 tons. According to capacity load, the rotator wheels are made of PU or FULL metals, which can ensure the support capacity and maintai...

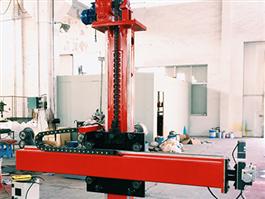

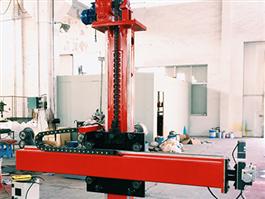

Pole Rotating Machine Motorized Elevation Self Centering PLC Connection with Robot Pole Rotating Machine Motorized Elevation Self Centering PLC Connection with Robot Technical Parameters:1. Pole length: 2-7 meter2. Two clamps distance: 2500mm3. Pole diameter: Max 350mm, min 70mm4. Pole clamp: pnuematic5. Motorized rotating for +/- 180dgr, with brake.6. Automatic rotate, automatic pause, controlled by PLC. Product Details Supply range (for each set):- Main body with motor & gearbox- Control system- Relative documents inc. mechanical drawings, electrical diagram, operation manual, etc. How to work: - The operator shall read the operation manual before start this machine. - Trial work the machine, be familiar with all controls, confirm every part work normally, done preparation before start working. - the working schedule is programmed into PLC. - Load the pole on the machine, level the pole body by motorized elevator, adjust the center line by the lead screw wheel, clamp by the gas cylinder. For second same size, no adjustment need be done. - Robot arm comes to weld two seams on flange. signal sent out to machine after welding done. - Machine receive the signal, rotate the pole 180deg. signal sent out to robot. - Robot comes to weld the rest two seams on flange. signal sent out to the machine. - Machine rotate back to 0 deg. worker release the gas cylinder to unload the pole. - Load second pole and clamp by the gas cylinder, start over. This machine is designed to reduce time and work for adjustment and level poles. By connecting to robot, the seams of flange could be welded automatically.

Welding Manipulator

Welding Manipulator

Welding Rotator

Welding Rotator

Welding Positioner

Welding Positioner

Plate Shot Blasting Machine

Plate Shot Blasting Machine

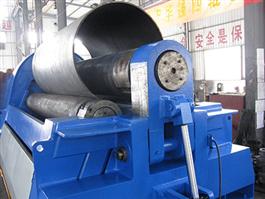

Plate Rolling Machine

Plate Rolling Machine

Welding Manipulator

Welding Manipulator