When it comes to the welding products,turning rolls are very useful equipments for the perfect positioning. The pipeturning rolls are mainly used for both positioning and rolling applicationsincluding...

When it comes to the welding products,turning rolls are very useful equipments for the perfect positioning. The pipeturning rolls are mainly used for both positioning and rolling applicationsincluding...

Self Aligning Rotator , Pipe Welding Rollers PU 20 Ton 1.5Kw Inverter Motor Self Aligning Rotator , Pipe Welding Rollers PU 20 Ton 1.5Kw Inverter Motor Pressure vessels are basic containers that hold gasses and liquids at different pressures. They are frequently used in industries and private sectors globally for pressure reactors, autoclaves, compression chambers, water storage, compressed air and much more. However, because they are dangerous in nature, their construction, development, and engineering are dictated by several parameters which determine the maximum operating temperature and pressure. Our welding rotator provide a safe and reliable service for welding pressure vessels. Product Details The Welding Rotators are built in capacities 20ton. The wheels are wrapped by thick PU, which can ensure the support capacity and last working long time. The specifications are as follow1. Each set includes 01 powered unit and 01 or more idler units with electrical control system.2. Both power unit and idler unit fit the tank automatically, no adjustment need for different diameters.3. Schneider / Mitsubishi inverter4. Schneider / Siemens/Omron electrical components5. Wireless Remote control for extreme long Job. 6. CE & ISO approved Model: GZ-20 (Self Align type) -Turning Capacity: 20T -Roller Diameter : Φ350mm -Roller width: 180 mm -Roller surface speed range: 100-1000mm / min (welding speed appx 200-300mm/min) -Loaded Vessel/Tank diameter range: Φ500-3500mm -Drive unit: variable frequency motor and qualified gearbox. -Wheel center adjustment (for both drive unit and Idler unit): Self Align Type. -Remote control: Remote control pendent with 18mtrs long Cable -Rotational speeds (variable speed AC drive): Step-less variable speeds are to be adjusted from min 100mm/min to max 1000mm/min by a potentiometer on the remote control through inverter. -Rollers: PU -Motor power: 1.5kW (variable frequency motor) -Gearbox ratio:1:40:30 -Power supply: 415V,50Hz, 3-P

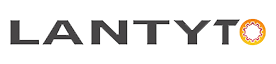

Welding Manipulator

Welding Manipulator

Welding Rotator

Welding Rotator

Welding Positioner

Welding Positioner

Plate Shot Blasting Machine

Plate Shot Blasting Machine

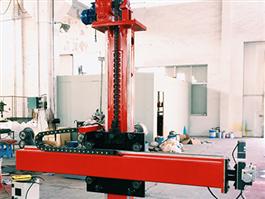

Plate Rolling Machine

Plate Rolling Machine

Welding Manipulator

Welding Manipulator