-

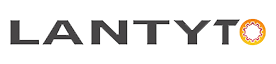

Welding Manipulator

Welding Manipulator

-

Welding Rotator

Welding Rotator

-

Welding Positioner

Welding Positioner

-

Customized Welding Solution

Customized Welding Solution

-

Plate Shot Blasting Machine

Plate Shot Blasting Machine

-

CNC Cutting Machine

CNC Cutting Machine

-

Edge Milling Machine

Edge Milling Machine

-

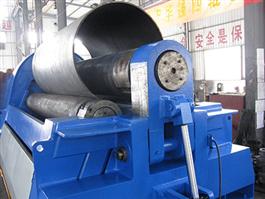

Plate Rolling Machine

Plate Rolling Machine

-

Welding Manipulator

Welding Manipulator

-

Fit-up Rotator

Fit-up Rotator

-

Fit-up Growing Line

Fit-up Growing Line

-

Sand Blasting Welding Rotator

Sand Blasting Welding Rotator

Custom metal fabricating company Metal Corbert, Shawinigan, Que., improvedcut quality, eliminated a bottleneck, expanded capacity, and brought outsourcedproduction back in-house. Metal Cor...

Welding is one of the important processing method in the manufacturing, due to the rapid development of modern science and technology and a number of factors, the welding process is experiencing...

-

Learn About Long Table Welding Rotator

The long table welding rotators are built in capacities from 5 ton to 250 ton.According to capacity load,the rotator wheels are of PU or FULL metals,which can ensure the support capacity and main...

-

Light Duty Turning Rolls

Light Duty Turning Rolls The light duty turning rolls built from min 1ton to max 5ton. Wheels are in 45# steel covered by PU. Foo...

Welding Rotator are mainly used in cylinder welding,such as marine,oil,gas,offshore,petro chemical,plate heat

exchanger,charged air cooler,pressure vessel,boiler.It has advantages of advanced technology,reliable quality

and simple operation so that is suitable for different diameter jobs in the range.

The welding rotator is classified into adjustable and self-adjustable types.Each set of welding rotator is comprised

of one powered unit and one idler unit with electrical control system.Two worm reducers of the driving wheel is

synchronous operation.The reducer is made up of frequency changing motor,frequency changer and etc.

Industrial boiler tank welding rotator is featured with low noise transmission,and stable turning under the welding

parameter in the range.Central distance of welding rotators can be adjusted upon customers' demand to save labor

force and increase working efficiency.