-

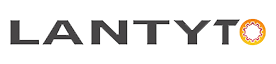

Welding Manipulator

Welding Manipulator

-

Welding Rotator

Welding Rotator

-

Welding Positioner

Welding Positioner

-

Customized Welding Solution

Customized Welding Solution

-

Plate Shot Blasting Machine

Plate Shot Blasting Machine

-

CNC Cutting Machine

CNC Cutting Machine

-

Edge Milling Machine

Edge Milling Machine

-

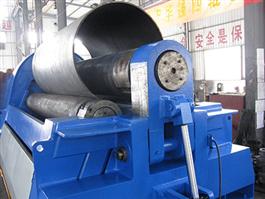

Plate Rolling Machine

Plate Rolling Machine

-

Welding Manipulator

Welding Manipulator

-

Fit-up Rotator

Fit-up Rotator

-

Fit-up Growing Line

Fit-up Growing Line

-

Sand Blasting Welding Rotator

Sand Blasting Welding Rotator

Initially used for nonferrous cutting operations, plasma developed into auseful means for cutting 2-D sheet and plate steel when the water-injectedplasma process was developed in the late 1960s. As te...

Pipeline welding plays an important part in both the onshore and offshore pipeline industry. Throughout the years there have been significant advancements to help ensure a pipelines durability and reliability. Here, Bob Teale takes us through the history and what’s to come.

Pipeline welding, as we know it today, started in 1927 with the introduction of Lincoln’s Fleetweld 5 cellulosic electrode. While there is no doubt that cellulosic electrodes have proven to be very effective and will remain so for years to come, they are technically limited in terms of strength, toughness, and production rates.

Once offshore pipeline construction started, there was a drive to increase production rates due to the cost of lay-barges and narrow weather windows. Initially this demand turned to using a semi-automatic CO2 gas metal arc welding (GMAW) process, but the high incidence of lack-of-fusion defects forced equipment developers to mechanise the process. While many tried, it was not until 1969 that CRC-Evans produced the first viable mechanised pipeline welding system.

The CRC mechanised system used a narrow 5° bevel, with the root deposited from the inside using a combination internal multi-head welder/clamp. The hot, fill, and cap passes were deposited externally using an orbital bug and guide band.

Despite efforts to build alternative systems, CRC dominated the landline industry for almost 25 years. This monopoly, however, was much shorter lived offshore. Within six years of the first mechanised welded offshore pipeline, Saipem introduced its PASSO system. which used a copper backing-clamp; with the root pass made, the remaining passes were deposited externally using an orbital bug.

Current welding technology

Most mechanised systems have now given way to computer controls and can be classed as automated systems. Today, pipeline contractors have the choice of using internal roots, external roots with copper backing, and external roots without backing. All of these root techniques are proven and have pros and cons. Internal roots produce the highest rates on land; they can also handle more alignment high/low, and do not need welders. Copper back-up clamps are cheaper than internal welders but have some risk of copper contamination and are 33–50 per cent slower.

The third-root pass option, external without backing, is based upon using a special short-arc transfer power supply. The first of these was developed by Lincoln Electric—STT (Surface Tension Transfer). The advantages of this process is that it is a much lower capital/rental cost, although on large diameter pipes, it is much slower. For example, on a 48 inch internal diameter girth weld, an internal root pass is almost twice as fast as an external copper root pass, and an external copper root pass is four times faster than no-backing root passes. Depending upon the diameter and length of the pipeline, as well as the schedule and the terrain, each root option may be cost-effective for the appropriate circumstances.

Fill-and-cap pass welding can now be accomplished using single or dual head bugs, or a combination of both. After the initial development of the band and bug single head machines, many efforts were made to build a dual head bug (PASSO, Evans Pipeline, CRC, B&R, and Astro-Arc), but it was Serimer-Dasa (now Serimax) who first produced a successful working dual head band and bug system. The impact of its dual head bug provided Serimer the opportunity to significantly increase production rates offshore where the number of weld stations is limited. While dual heads do not double production, they will increase deposition by 40–50 per cent – dual head-bugs require fewer weld stations, fewer welders, and fewer side booms.

The latest developments

Current automated pipeline welding developments tend to be centred on improved seam tracking, data logging and stronger line-up clamps. Most equipment suppliers are taking advantage of increased computing power to improve through-the-arc tracking, contact-to-work distance and arc voltage controls, and laser tracking is also available. Advanced tracking technology improves weld quality, and consistency, and improves production rates by allowing faster travel speeds. In addition to the major automated welding equipment suppliers/users, there are now many alternative suppliers of single head orbital machines. Some are still mechanised units but work well with flux-cored arc welding wires.